NEW

What Product Types Does the Resistor Factory Include?

I. Introduction

A. Definition of Resistors

Resistors are fundamental electronic components that limit the flow of electric current in a circuit. They are designed to provide a specific resistance value, measured in ohms, which helps control voltage and current levels. Resistors play a crucial role in ensuring that electronic devices function correctly and safely.

B. Importance of Resistors in Electronic Circuits

In electronic circuits, resistors are essential for various functions, including voltage division, current limiting, and signal conditioning. They help protect sensitive components from excessive current and voltage, ensuring the longevity and reliability of electronic devices. Without resistors, circuits would be prone to failure, leading to malfunctions and potential hazards.

C. Overview of the Resistor Factory's Role in Manufacturing

Resistor factories are specialized manufacturing facilities that produce a wide range of resistors to meet the demands of various industries. These factories employ advanced technologies and processes to ensure high-quality products that adhere to industry standards. Understanding the different types of resistors produced in these factories is crucial for anyone involved in electronics, from hobbyists to engineers.

II. Types of Resistors

Resistor factories produce several types of resistors, each designed for specific applications and performance requirements. The main categories include fixed resistors, variable resistors, and specialty resistors.

A. Fixed Resistors

Fixed resistors have a predetermined resistance value that does not change. They are the most common type of resistor and are used in various applications.

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a relatively high tolerance and are less stable than other types.

2. **Carbon Film Resistors**: These resistors are made by depositing a thin layer of carbon on a ceramic substrate. They offer better stability and lower noise than carbon composition resistors, making them suitable for audio applications.

3. **Metal Film Resistors**: Constructed from a thin film of metal, these resistors provide high precision and low temperature coefficient. They are commonly used in applications requiring high accuracy, such as instrumentation.

4. **Wirewound Resistors**: Made by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications.

5. **Thick Film Resistors**: These resistors are made by printing a thick layer of resistive material onto a substrate. They are widely used in surface-mount technology (SMT) due to their compact size and reliability.

6. **Thin Film Resistors**: Similar to thick film resistors but with a thinner layer of resistive material, thin film resistors offer superior precision and stability, making them ideal for high-frequency applications.

B. Variable Resistors

Variable resistors allow users to adjust the resistance value, making them versatile components in electronic circuits.

1. **Potentiometers**: These are three-terminal devices that can be used to adjust voltage levels in a circuit. They are commonly found in volume controls and other adjustable settings.

2. **Rheostats**: A type of variable resistor, rheostats are used to control current flow in a circuit. They are often employed in applications requiring high power, such as lighting controls.

3. **Trimmers**: These small variable resistors are used for fine-tuning circuits. They are typically adjusted only once during the setup of a device and are found in applications like radio tuning.

C. Specialty Resistors

Specialty resistors are designed for specific applications and often have unique properties.

1. **Fusible Resistors**: These resistors are designed to act as a fuse, breaking the circuit when a certain current level is exceeded. They provide protection against overcurrent conditions.

2. **High Voltage Resistors**: Built to withstand high voltage levels, these resistors are used in applications such as power supplies and high-voltage testing equipment.

3. **Precision Resistors**: Offering tight tolerance levels, precision resistors are used in applications where accuracy is critical, such as in measurement devices.

4. **Current Sensing Resistors**: These resistors are used to measure current flow in a circuit. They are often employed in power management systems and battery monitoring applications.

5. **Thermistors**: Temperature-sensitive resistors, thermistors change resistance with temperature variations. They are commonly used in temperature sensing and control applications.

6. **Varistors**: Voltage-dependent resistors, varistors protect circuits from voltage spikes by changing resistance based on the applied voltage. They are often used in surge protection devices.

III. Manufacturing Processes

The manufacturing of resistors involves several key processes, from material selection to quality control.

A. Material Selection

1. **Conductive Materials**: The choice of conductive materials, such as carbon, metal, or metal oxide, significantly impacts the performance of the resistor. Each material has its own characteristics, such as temperature coefficient and stability.

2. **Insulating Materials**: Insulating materials are crucial for preventing unwanted current flow and ensuring the safety of the resistor. Common insulating materials include ceramics and plastics.

B. Production Techniques

1. **Automated Assembly**: Many resistor factories utilize automated assembly lines to increase efficiency and reduce production costs. Automation allows for precise manufacturing and consistent quality.

2. **Hand Assembly**: In some cases, especially for specialty or low-volume resistors, hand assembly is employed. Skilled technicians assemble these components to ensure quality and attention to detail.

3. **Quality Control Measures**: Rigorous quality control measures are implemented throughout the manufacturing process to ensure that resistors meet industry standards. This includes inspections at various stages of production.

C. Testing and Certification

1. **Electrical Testing**: Resistors undergo electrical testing to verify their resistance values and performance characteristics. This ensures that they function as intended in their applications.

2. **Environmental Testing**: Resistors are subjected to environmental testing to assess their performance under different conditions, such as temperature and humidity variations.

3. **Compliance with Industry Standards**: Resistor manufacturers must adhere to industry standards, such as those set by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), to ensure product reliability and safety.

IV. Applications of Resistors

Resistors are used in a wide range of applications across various industries.

A. Consumer Electronics

In consumer electronics, resistors are found in devices such as televisions, smartphones, and computers, where they help regulate current and voltage levels.

B. Automotive Industry

Resistors play a critical role in automotive applications, including engine control units, lighting systems, and safety features, ensuring proper functionality and safety.

C. Industrial Equipment

In industrial settings, resistors are used in machinery and control systems, helping to manage power levels and protect sensitive components.

D. Telecommunications

Telecommunication devices rely on resistors for signal processing and conditioning, ensuring clear and reliable communication.

E. Medical Devices

In medical devices, precision resistors are essential for accurate measurements and reliable performance, contributing to patient safety and effective treatment.

V. Innovations in Resistor Technology

The resistor industry is continually evolving, with innovations aimed at improving performance and sustainability.

A. Miniaturization of Resistors

As electronic devices become smaller and more compact, the demand for miniaturized resistors has increased. Manufacturers are developing smaller, more efficient resistors that maintain performance without compromising size.

B. Development of Smart Resistors

Smart resistors equipped with sensors and communication capabilities are emerging, allowing for real-time monitoring and adjustments in electronic circuits.

C. Eco-Friendly Manufacturing Practices

With growing environmental concerns, resistor manufacturers are adopting eco-friendly practices, such as using sustainable materials and reducing waste in the production process.

D. Advances in Material Science

Research in material science is leading to the development of new resistor materials that offer improved performance, stability, and reliability, paving the way for next-generation electronic devices.

VI. Conclusion

A. Summary of Resistor Types and Their Importance

Resistors are vital components in electronic circuits, with various types designed for specific applications. From fixed and variable resistors to specialty options, each type plays a crucial role in ensuring the functionality and safety of electronic devices.

B. Future Trends in Resistor Manufacturing

As technology advances, the resistor manufacturing industry will continue to evolve, focusing on miniaturization, smart technologies, and sustainable practices to meet the demands of modern electronics.

C. The Role of Resistor Factories in Advancing Technology

Resistor factories are at the forefront of innovation in the electronics industry, producing high-quality components that enable the development of advanced technologies. Their role is essential in driving progress and ensuring the reliability of electronic devices across various applications.

VII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Reports

- Resistor Market Analysis Report

- Global Electronic Components Market Report

C. Manufacturer Specifications

- Datasheets from leading resistor manufacturers

- Technical specifications from industry standards organizations

D. Online Resources and Databases

- Electronics tutorials and educational websites

- Industry news and updates from electronics trade publications

This comprehensive overview of resistor types and their manufacturing processes highlights the importance of resistors in modern electronics and the ongoing innovations that shape the industry. Understanding these components is essential for anyone involved in electronics, from design to application.

Comparative Differences Between Mainstream Neutral Point Resistor Models

I. Introduction

In the realm of electrical engineering, the Neutral Point Resistor (NPR) plays a crucial role in ensuring the stability and safety of electrical systems, particularly in three-phase power systems. An NPR is a resistor connected to the neutral point of a transformer or generator, serving to limit fault currents and provide a path for unbalanced loads. Understanding the various models of NPRs is essential for engineers and technicians who design and maintain electrical systems. This blog post aims to compare mainstream NPR models, highlighting their key features, performance metrics, and applications.

II. Overview of Neutral Point Resistor Models

A. Explanation of Neutral Point Resistor Functionality

The primary function of an NPR is to provide a controlled path for fault currents during short circuits or ground faults. By doing so, it helps to stabilize the voltage levels in the system and protects equipment from damage. NPRs also facilitate the detection of ground faults, which is critical for maintaining system integrity.

B. Common Applications of NPRs

NPRs are widely used in various applications, including:

- Power generation and distribution systems

- Industrial motor drives

- Renewable energy systems, such as wind and solar power

- Railways and electric traction systems

C. Types of NPR Models in Use

There are several types of NPR models available in the market, each designed to meet specific operational requirements. These include resistive, inductive, and hybrid models, each with its unique characteristics and applications.

III. Key Features of Mainstream NPR Models

A. Design and Construction

1. Material Composition

The materials used in the construction of NPRs significantly influence their performance. Common materials include:

- Steel: Offers durability and strength.

- Copper: Provides excellent conductivity.

- Aluminum: Lightweight and cost-effective.

2. Physical Dimensions

The size and shape of NPRs can vary based on their intended application. Compact models are suitable for limited spaces, while larger models may be required for high-power applications.

B. Electrical Characteristics

1. Resistance Values

NPRs come in various resistance values, typically ranging from a few ohms to several hundred ohms. The choice of resistance value depends on the specific application and the desired level of fault current limitation.

2. Power Ratings

Power ratings indicate the maximum power an NPR can handle without overheating. This is a critical factor in ensuring the reliability and longevity of the resistor.

3. Thermal Performance

Thermal performance is essential for maintaining operational efficiency. NPRs must be able to dissipate heat generated during fault conditions effectively.

C. Safety Features

1. Overcurrent Protection

Many NPR models include built-in overcurrent protection mechanisms to prevent damage during fault conditions.

2. Insulation and Isolation

Proper insulation and isolation are vital for ensuring the safety of personnel and equipment. High-quality NPRs are designed to withstand high voltages and prevent electrical arcing.

IV. Comparative Analysis of Mainstream NPR Models

A. Model A: Description and Key Features

**Description:** Model A is a resistive NPR designed for medium-voltage applications.

**Applications:** Commonly used in industrial power systems and renewable energy installations.

**Advantages:**

- High thermal performance

- Compact design suitable for limited spaces

**Limitations:**

- Higher cost compared to other models

- Limited resistance range

B. Model B: Description and Key Features

**Description:** Model B is an inductive NPR that provides additional fault current limiting capabilities.

**Applications:** Ideal for high-power applications, such as large industrial motors and generators.

**Advantages:**

- Enhanced fault current limiting

- Robust construction for harsh environments

**Limitations:**

- Bulkier design may require more installation space

- Higher maintenance requirements

C. Model C: Description and Key Features

**Description:** Model C is a hybrid NPR that combines resistive and inductive elements.

**Applications:** Suitable for a wide range of applications, including power distribution and renewable energy systems.

**Advantages:**

- Versatile and adaptable to various conditions

- Balanced performance characteristics

**Limitations:**

- More complex design may lead to higher costs

- Requires careful selection based on specific application needs

V. Performance Metrics

A. Efficiency and Reliability

Efficiency is a critical metric for evaluating NPR models. High-efficiency models minimize energy losses during operation, contributing to overall system reliability. Reliability is assessed based on the model's ability to perform consistently under varying conditions.

B. Cost-Effectiveness

Cost-effectiveness is a significant consideration for engineers and project managers. While some models may have a higher upfront cost, their long-term performance and reliability can justify the investment.

C. Maintenance Requirements

Maintenance requirements vary among NPR models. Some models may require regular inspections and replacements, while others are designed for minimal maintenance, making them more appealing for long-term use.

D. Environmental Impact

The environmental impact of NPR models is becoming increasingly important. Models that utilize sustainable materials and have lower energy consumption are preferred in modern applications.

VI. Case Studies

A. Real-World Applications of Different NPR Models

1. **Model A in a Wind Farm:** Model A was implemented in a wind farm to manage fault currents effectively. The compact design allowed for easy installation, and the high thermal performance ensured reliability during peak loads.

2. **Model B in an Industrial Plant:** Model B was used in a large industrial plant with high-power motors. Its inductive properties provided excellent fault current limiting, although the bulkier design required careful planning during installation.

3. **Model C in a Solar Power Facility:** Model C was selected for a solar power facility due to its versatility. The hybrid design allowed for effective management of varying load conditions, resulting in improved system performance.

B. Performance Outcomes and User Feedback

User feedback from these case studies highlighted the importance of selecting the right NPR model based on specific application needs. While Model A excelled in compact spaces, Model B's robustness was favored in high-power environments.

C. Lessons Learned from Case Studies

The case studies underscored the necessity of thorough evaluation and testing before selecting an NPR model. Understanding the unique requirements of each application is crucial for ensuring optimal performance.

VII. Future Trends in NPR Technology

A. Innovations in Design and Materials

The future of NPR technology is likely to see innovations in design and materials, focusing on enhancing efficiency and reducing environmental impact. Advanced materials, such as composites and nanomaterials, may offer improved thermal performance and durability.

B. Emerging Applications and Markets

As renewable energy sources continue to grow, the demand for efficient NPR models will increase. Emerging markets, such as electric vehicles and smart grids, will also drive innovation in NPR technology.

C. Predictions for the Evolution of NPR Models

The evolution of NPR models will likely focus on integrating smart technology, allowing for real-time monitoring and diagnostics. This will enhance reliability and facilitate proactive maintenance.

VIII. Conclusion

In conclusion, understanding the comparative differences between mainstream neutral point resistor models is essential for engineers and technicians involved in electrical system design and maintenance. Each model offers unique features, advantages, and limitations, making it crucial to select the appropriate NPR based on specific application needs. As technology continues to evolve, staying informed about the latest trends and innovations in NPR technology will be vital for ensuring the safety and efficiency of electrical systems.

IX. References

- Academic Journals on Electrical Engineering

- Industry Reports on Power Systems

- Manufacturer Specifications and Guidelines for NPR Models

This comprehensive exploration of NPR models provides valuable insights for professionals in the field, ensuring informed decision-making and optimal system performance.

The Role of Lifting Resistor Products in Practical Applications

I. Introduction

In the world of electronics, the importance of every component cannot be overstated. Among these components, lifting resistors play a crucial role in ensuring the stability and reliability of electrical and electronic systems. But what exactly are lifting resistors, and why are they so vital? This article aims to explore the definition, functionality, applications, benefits, considerations, and future trends of lifting resistor products, providing a comprehensive understanding of their role in practical applications.

II. Understanding Lifting Resistors

A. What are Lifting Resistors?

Lifting resistors, often referred to as pull-up or pull-down resistors, are passive electronic components used to ensure that a circuit input is at a defined logic level.

1. **Technical Definition**: A lifting resistor is connected to a voltage source or ground to pull the input pin of a digital circuit to a high or low state when no active devices are driving the pin.

2. **Types of Lifting Resistors**:

- **Pull-Up Resistors**: These resistors connect the input to a positive voltage (usually the supply voltage) to ensure that the input reads a high state when not actively driven low.

- **Pull-Down Resistors**: Conversely, pull-down resistors connect the input to ground, ensuring that the input reads a low state when not actively driven high.

B. How Lifting Resistors Function

1. **Basic Electrical Principles**: Lifting resistors work on the principle of voltage division and current flow. By providing a path to either the supply voltage or ground, they help maintain a stable voltage level at the input pin.

2. **Role in Circuit Design**: In circuit design, lifting resistors are essential for preventing floating inputs, which can lead to unpredictable behavior in digital circuits. They ensure that inputs are always at a defined state, thus enhancing the reliability of the system.

III. Applications of Lifting Resistors

A. Digital Circuits

In digital circuits, lifting resistors are fundamental for ensuring stable logic levels. They prevent floating inputs, which can cause erratic behavior and unreliable operation. For instance, in a microcontroller, if an input pin is left unconnected, it may pick up noise and fluctuate between high and low states. A pull-up or pull-down resistor mitigates this issue by providing a defined state.

B. Microcontroller and Microprocessor Systems

Microcontrollers and microprocessors often have multiple input pins that require proper configuration. Lifting resistors play a vital role in input pin configuration, ensuring that the pins are at a known state during startup and when not actively driven. This is crucial for maintaining signal integrity and reducing noise, which can lead to erroneous readings and system failures.

C. Communication Systems

In communication systems, lifting resistors enhance data transmission reliability. They help in signal conditioning by ensuring that the signals are at the correct logic levels, thus preventing data corruption during transmission. This is particularly important in high-speed communication protocols where signal integrity is paramount.

D. Power Supply Circuits

Lifting resistors also find applications in power supply circuits. They can assist in voltage regulation by providing a load that helps stabilize the output voltage. Additionally, they can aid in load balancing by ensuring that the current is evenly distributed across multiple components, thus enhancing the overall efficiency of the power supply system.

IV. Benefits of Using Lifting Resistors

A. Improved Circuit Stability

One of the primary benefits of using lifting resistors is improved circuit stability. By reducing noise and interference, they enhance signal clarity, which is essential for the reliable operation of electronic systems.

B. Increased Reliability

Lifting resistors contribute to increased reliability by preventing erroneous signals. By ensuring that inputs are at a defined state, they reduce the likelihood of false triggering and system malfunctions. This reliability extends the lifespan of components, as they are less likely to be subjected to erratic behavior.

C. Cost-Effectiveness

Lifting resistors are low-cost components that can simplify circuit design. Their implementation can reduce the need for more complex circuitry, making them a cost-effective solution for many applications. This simplicity can also lead to faster design cycles and reduced time-to-market for new products.

V. Considerations When Implementing Lifting Resistors

A. Choosing the Right Resistor Value

When implementing lifting resistors, choosing the right resistor value is crucial. The resistor value impacts current flow and power consumption. A resistor that is too low can draw excessive current, leading to power inefficiency, while a resistor that is too high may not provide sufficient pull strength to maintain the desired logic level.

B. Placement in Circuit Design

The placement of lifting resistors in circuit design is another important consideration. Proximity to components can affect performance, and careful layout considerations can help minimize noise. Proper placement can enhance the effectiveness of the lifting resistors and improve overall circuit performance.

C. Environmental Factors

Environmental factors such as temperature and humidity can affect the performance of lifting resistors. Selecting materials that can withstand varying conditions is essential for ensuring durability and reliability in different environments.

VI. Case Studies

A. Example 1: Lifting Resistors in Consumer Electronics

In consumer electronics, lifting resistors are commonly used in smartphones. They help maintain stable logic levels for touchscreens and buttons, ensuring a responsive user experience. The impact of lifting resistors on performance is significant, as they prevent false inputs and enhance the reliability of the device.

B. Example 2: Lifting Resistors in Industrial Automation

In industrial automation, lifting resistors play a crucial role in sensor systems. They ensure that sensor outputs are at defined logic levels, enhancing operational efficiency. By providing stable signals, lifting resistors contribute to the overall reliability of automated systems, reducing downtime and maintenance costs.

VII. Future Trends and Innovations

A. Advances in Resistor Technology

The future of lifting resistors is promising, with advances in resistor technology paving the way for smarter and more adaptive systems. Smart resistors that can adjust their resistance based on environmental conditions or circuit requirements are on the horizon. Additionally, the integration of lifting resistors with IoT devices will enhance their functionality and applicability in modern electronics.

B. Evolving Applications

As technology evolves, so do the applications of lifting resistors. Emerging fields such as renewable energy and electric vehicles present new opportunities for lifting resistors in circuit designs. The potential for innovative circuit designs that leverage lifting resistors is vast, promising exciting developments in the future.

VIII. Conclusion

In conclusion, lifting resistors are essential components in modern electronics, playing a vital role in ensuring stability, reliability, and cost-effectiveness in various applications. Their ability to maintain defined logic levels and prevent floating inputs makes them indispensable in digital circuits, microcontroller systems, communication systems, and power supply circuits. As technology continues to advance, the importance of lifting resistors will only grow, making it crucial for engineers and designers to understand their functionality and applications. By exploring and embracing the potential of lifting resistors, we can enhance the performance and reliability of electronic systems in the future.

IX. References

1. Academic papers and articles on lifting resistors and their applications.

2. Industry standards and guidelines related to electronic component design.

3. Relevant textbooks and resources for further reading on circuit design and electronic components.

This comprehensive exploration of lifting resistors highlights their significance in practical applications, encouraging further investigation and understanding of these vital components in the field of electronics.

What are the Purchasing Models of the Latest Automotive Resistors and Equipment Components?

I. Introduction

The automotive industry is undergoing a significant transformation, driven by advancements in technology and a growing emphasis on sustainability. As vehicles become increasingly reliant on electronic components, the demand for high-quality automotive resistors and equipment components has surged. These components play a crucial role in ensuring vehicle performance, safety, and efficiency. This article aims to explore the various purchasing models for automotive resistors and equipment components, shedding light on how manufacturers and suppliers navigate this evolving landscape.

II. Understanding Automotive Resistors and Equipment Components

A. Definition and Types of Automotive Resistors

Automotive resistors are essential components that regulate the flow of electrical current within a vehicle's electronic systems. They come in various types, including:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in applications where a specific resistance is required.

2. **Variable Resistors**: Also known as potentiometers, these resistors allow for adjustable resistance, making them ideal for applications like volume controls and temperature sensors.

3. **Specialty Resistors**: These include high-power resistors, precision resistors, and those designed for specific automotive applications, such as load resistors for LED lighting.

B. Overview of Equipment Components in Automotive Applications

In addition to resistors, various equipment components are critical to modern vehicles, including:

1. **Sensors**: These devices monitor various parameters, such as temperature, pressure, and speed, providing essential data for vehicle control systems.

2. **Actuators**: Actuators convert electrical signals into mechanical movement, playing a vital role in systems like power steering and braking.

3. **Control Units**: These electronic control units (ECUs) manage and coordinate the functions of various automotive systems, ensuring optimal performance.

C. Role of These Components in Vehicle Performance and Safety

The integration of resistors and equipment components is vital for enhancing vehicle performance and safety. For instance, sensors provide real-time data that enables advanced driver-assistance systems (ADAS), while control units ensure that all electronic systems work harmoniously. As vehicles become more complex, the importance of high-quality components cannot be overstated.

III. Current Trends in Automotive Component Purchasing

A. Shift Towards Electronic Vehicles (EVs) and Its Impact on Component Demand

The automotive industry is witnessing a significant shift towards electric vehicles (EVs), which has a profound impact on component demand. EVs require specialized resistors and equipment components to manage battery systems, regenerative braking, and electric drivetrains. This shift is driving manufacturers to seek innovative solutions and suppliers who can provide cutting-edge technology.

B. Increasing Complexity of Automotive Systems and the Need for Specialized Components

As vehicles become more sophisticated, the complexity of their electronic systems increases. This complexity necessitates the use of specialized components that can meet stringent performance and reliability standards. Manufacturers are now looking for suppliers who can offer tailored solutions that address specific challenges in automotive applications.

C. The Role of Sustainability and Eco-Friendly Materials in Purchasing Decisions

Sustainability is becoming a key consideration in purchasing decisions. Manufacturers are increasingly prioritizing eco-friendly materials and processes, leading to a demand for components that align with environmental standards. This trend is not only driven by regulatory requirements but also by consumer preferences for greener vehicles.

IV. Purchasing Models in the Automotive Industry

A. Traditional Purchasing Model

The traditional purchasing model involves a straightforward approach where manufacturers source components from suppliers based on established contracts and agreements. This model has its advantages, such as predictability and stability, but it can also lead to inefficiencies and higher costs due to lack of flexibility.

B. Just-In-Time (JIT) Purchasing Model

The Just-In-Time (JIT) purchasing model focuses on minimizing inventory costs by ordering components only as they are needed in the production process. This model offers several benefits for automotive manufacturers, including reduced storage costs and improved cash flow. However, it also presents challenges, such as the risk of supply chain disruptions and the need for reliable suppliers.

C. Strategic Sourcing Model

Strategic sourcing involves a comprehensive approach to procurement, emphasizing long-term relationships with suppliers. This model allows manufacturers to leverage supplier expertise, negotiate better terms, and achieve cost savings over time. By fostering collaboration, manufacturers can ensure a steady supply of high-quality components that meet their evolving needs.

D. E-Procurement and Digital Platforms

The rise of e-procurement and digital platforms has revolutionized the purchasing process in the automotive industry. Online marketplaces enable manufacturers to access a wide range of components and suppliers, streamlining the procurement process. E-procurement systems offer benefits such as improved efficiency, better tracking of orders, and enhanced data analytics capabilities. Successful case studies demonstrate how companies have leveraged these platforms to optimize their purchasing strategies.

V. Factors Influencing Purchasing Decisions

Several factors influence purchasing decisions in the automotive industry:

A. Quality and Reliability of Components

Quality and reliability are paramount when selecting automotive components. Manufacturers prioritize suppliers with a proven track record of delivering high-quality products that meet industry standards.

B. Cost Considerations and Budget Constraints

Cost is a critical factor in purchasing decisions. Manufacturers must balance the need for quality with budget constraints, often seeking competitive pricing without compromising on performance.

C. Supplier Reputation and Track Record

The reputation of suppliers plays a significant role in purchasing decisions. Manufacturers prefer to work with established suppliers known for their reliability, responsiveness, and ability to meet deadlines.

D. Regulatory Compliance and Industry Standards

Compliance with regulatory requirements and industry standards is essential in the automotive sector. Manufacturers must ensure that components meet safety and environmental regulations, influencing their purchasing choices.

E. Technological Advancements and Innovation

Technological advancements drive innovation in automotive components. Manufacturers are increasingly looking for suppliers who can provide cutting-edge solutions that enhance vehicle performance and safety.

VI. The Role of Suppliers and Manufacturers

A. Overview of Key Players in the Automotive Resistor and Equipment Component Market

The automotive resistor and equipment component market is characterized by a diverse range of suppliers, from large multinational corporations to specialized manufacturers. Key players include companies that focus on high-performance resistors, sensors, and control units.

B. Importance of Collaboration Between Manufacturers and Suppliers

Collaboration between manufacturers and suppliers is crucial for success in the automotive industry. By working closely together, both parties can share insights, address challenges, and develop innovative solutions that meet market demands.

C. Trends in Supplier Selection and Evaluation

Trends in supplier selection and evaluation are evolving, with manufacturers increasingly prioritizing factors such as sustainability, technological capabilities, and responsiveness. This shift reflects the changing dynamics of the automotive industry and the need for agile supply chains.

VII. Future Outlook for Automotive Resistor and Equipment Component Purchasing

A. Predictions for Market Growth and Demand

The automotive resistor and equipment component market is expected to experience significant growth in the coming years, driven by the increasing adoption of electric vehicles and advancements in automotive technology. Manufacturers will continue to seek innovative solutions to meet evolving consumer demands.

B. Emerging Technologies and Their Impact on Purchasing Models

Emerging technologies, such as artificial intelligence and machine learning, are poised to transform purchasing models in the automotive industry. These technologies can enhance data analytics capabilities, improve supplier selection processes, and streamline procurement operations.

C. The Role of Artificial Intelligence and Data Analytics in Procurement

Artificial intelligence and data analytics will play a pivotal role in shaping the future of procurement in the automotive sector. By leveraging data-driven insights, manufacturers can make informed purchasing decisions, optimize inventory management, and enhance supplier relationships.

VIII. Conclusion

Understanding the purchasing models for automotive resistors and equipment components is essential for manufacturers navigating the complexities of the automotive industry. As the landscape continues to evolve, stakeholders must adapt to changing dynamics, prioritize quality and sustainability, and embrace innovative technologies. By doing so, they can ensure a competitive edge in a rapidly changing market.

IX. References

A comprehensive list of academic papers, industry reports, and relevant articles will be provided to support the research and insights presented in this article.

---

This blog post provides a detailed exploration of the purchasing models for automotive resistors and equipment components, highlighting the importance of understanding these dynamics in the context of an evolving automotive landscape.

What are the Main Application Directions of Resistor Classification?

I. Introduction

A. Definition of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are fundamental to the operation of electronic devices, serving various functions such as voltage division, current limiting, and signal conditioning. Resistors are characterized by their resistance value, which is measured in ohms (Ω), and they play a crucial role in ensuring that electronic circuits function correctly and efficiently.

B. Importance of Resistor Classification

The classification of resistors is essential for several reasons. It helps engineers and designers select the appropriate type of resistor for specific applications, ensuring optimal performance and reliability. Different resistors have unique characteristics, such as power ratings, tolerance levels, and temperature coefficients, which influence their suitability for various tasks. By understanding the classification of resistors, professionals can make informed decisions that enhance the functionality and longevity of electronic devices.

C. Overview of Application Directions

Resistors find applications across a wide range of industries, from consumer electronics to renewable energy systems. This blog post will explore the main application directions of resistor classification, highlighting how different types of resistors are utilized in various fields.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a constant resistance value and are the most commonly used type of resistor. They come in various forms, including:

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a relatively high tolerance and are less stable than other types.

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability, lower noise, and tighter tolerances compared to carbon composition resistors, making them suitable for precision applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in applications requiring high precision and stability.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits. The two main types are:

1. **Potentiometers**: These are used to control voltage levels in circuits, such as in volume controls for audio equipment. They consist of a resistive element and a movable wiper that adjusts the resistance.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit. They are typically used in applications where high power is required, such as in lighting control systems.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations. They are commonly used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light intensity. They are often used in light-sensing applications, such as automatic lighting systems.

3. **Varistors**: These voltage-dependent resistors protect circuits from voltage spikes by changing resistance with applied voltage. They are commonly used in surge protection devices.

III. Application Directions of Resistor Classification

A. Consumer Electronics

Resistors play a vital role in consumer electronics, where they are used in various devices:

1. **Audio Equipment**: In audio systems, resistors are used in equalizers, amplifiers, and tone controls to manage signal levels and improve sound quality.

2. **Home Appliances**: Resistors are found in appliances like washing machines and microwaves, where they help regulate power and control functions.

3. **Mobile Devices**: In smartphones and tablets, resistors are used in power management circuits, display controls, and audio processing.

B. Industrial Applications

In industrial settings, resistors are crucial for:

1. **Automation and Control Systems**: Resistors are used in sensors and control circuits to ensure accurate readings and reliable operation.

2. **Power Distribution**: In power systems, resistors help manage load and protect equipment from overloads.

3. **Measurement and Testing Equipment**: Precision resistors are essential in testing devices, ensuring accurate measurements in laboratories and industrial environments.

C. Automotive Industry

The automotive industry relies heavily on resistors for:

1. **Engine Control Units (ECUs)**: Resistors are used in ECUs to manage engine performance, fuel efficiency, and emissions control.

2. **Safety Systems**: Resistors play a role in airbag systems, anti-lock braking systems (ABS), and other safety features, ensuring reliable operation.

3. **Infotainment Systems**: In-car entertainment systems utilize resistors for audio processing, display controls, and connectivity features.

D. Telecommunications

In telecommunications, resistors are essential for:

1. **Signal Processing**: Resistors are used in amplifiers and filters to manage signal strength and quality.

2. **Network Equipment**: Resistors are found in routers, switches, and other networking devices, ensuring proper signal transmission and reception.

3. **RF Applications**: In radio frequency applications, resistors help control signal levels and impedance matching.

E. Medical Devices

Resistors are critical in the medical field for:

1. **Diagnostic Equipment**: Resistors are used in devices like ECG machines and blood pressure monitors to ensure accurate readings.

2. **Therapeutic Devices**: In devices such as defibrillators and infusion pumps, resistors help regulate power and control functions.

3. **Monitoring Systems**: Resistors are essential in patient monitoring systems, ensuring reliable data transmission and processing.

F. Renewable Energy Systems

In renewable energy applications, resistors are used in:

1. **Solar Inverters**: Resistors help manage power conversion and ensure efficient energy transfer from solar panels to the grid.

2. **Wind Turbines**: Resistors are used in control systems to manage power output and protect against overloads.

3. **Energy Storage Systems**: In battery management systems, resistors help regulate charging and discharging processes.

IV. Factors Influencing Resistor Selection

When selecting resistors for specific applications, several factors must be considered:

A. Resistance Value

The resistance value must match the requirements of the circuit to ensure proper functionality.

B. Power Rating

Resistors have power ratings that indicate the maximum power they can handle without overheating. Selecting a resistor with an appropriate power rating is crucial for reliability.

C. Tolerance and Temperature Coefficient

Tolerance indicates how much the actual resistance can vary from the specified value, while the temperature coefficient indicates how resistance changes with temperature. Both factors are essential for precision applications.

D. Size and Form Factor

The physical size and form factor of the resistor must fit within the design constraints of the circuit or device.

E. Environmental Considerations

Factors such as humidity, temperature, and exposure to chemicals can affect resistor performance. Selecting resistors that can withstand environmental conditions is vital for long-term reliability.

V. Future Trends in Resistor Technology

As technology advances, several trends are shaping the future of resistor technology:

A. Miniaturization and Integration

The demand for smaller electronic devices is driving the miniaturization of resistors. Integrated resistors, which combine resistive elements with other components on a single chip, are becoming more common.

B. Smart Resistors and IoT Applications

With the rise of the Internet of Things (IoT), smart resistors that can communicate and adapt to changing conditions are emerging. These resistors can enhance the functionality of connected devices.

C. Advances in Materials and Manufacturing Techniques

Innovations in materials science and manufacturing processes are leading to the development of more efficient and reliable resistors. New materials can improve performance, reduce size, and enhance durability.

VI. Conclusion

A. Summary of Key Points

Resistors are essential components in electronic circuits, classified into various types based on their characteristics and applications. Understanding resistor classification is crucial for selecting the right components for specific applications across diverse industries.

B. The Role of Resistor Classification in Modern Technology

Resistor classification plays a vital role in modern technology, enabling engineers and designers to create efficient, reliable, and high-performing electronic devices.

C. Final Thoughts on the Importance of Resistors in Various Applications

As technology continues to evolve, the importance of resistors in various applications will only grow. From consumer electronics to renewable energy systems, resistors remain fundamental to the functionality and reliability of electronic devices, underscoring their significance in our increasingly connected world.

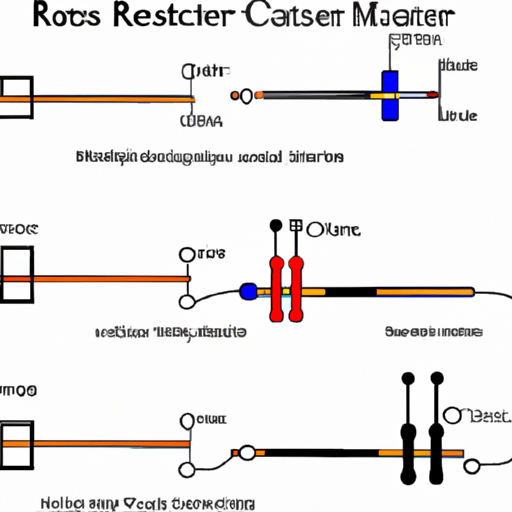

Mainstream Resistor Circuit Symbols Product Series Parameters

I. Introduction

A. Definition of Resistors

Resistors are fundamental components in electronic circuits, designed to limit the flow of electric current. They are passive devices that convert electrical energy into heat, thereby controlling the voltage and current within a circuit. Resistors are characterized by their resistance value, measured in ohms (Ω), which determines how much they resist the flow of current.

B. Importance of Resistor Circuit Symbols

In the realm of electronics, circuit diagrams serve as blueprints for understanding and constructing circuits. Resistor circuit symbols are essential for conveying information about the type and function of resistors within these diagrams. They provide a universal language that engineers and technicians can use to communicate complex ideas succinctly and clearly.

C. Overview of the Product Series Parameters

Understanding the parameters associated with resistor products is crucial for selecting the right component for a specific application. This blog post will delve into the various resistor circuit symbols, types of resistors, key parameters, and practical applications, providing a comprehensive guide for anyone looking to deepen their knowledge of resistors in electronic circuits.

II. Understanding Resistor Circuit Symbols

A. Basic Resistor Symbol

The basic resistor symbol is a simple zigzag line in schematic diagrams. This representation is widely recognized and used in various standards, including the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). While the zigzag symbol is common, variations exist, such as a rectangular box used in some contexts.

B. Specialized Resistor Symbols

1. **Variable Resistors**: Represented by a similar zigzag line with an arrow indicating the adjustable part, variable resistors allow for changes in resistance.

2. **Potentiometers**: A specific type of variable resistor, potentiometers are depicted with three terminals and an adjustable slider.

3. **Thermistors**: These temperature-sensitive resistors are often represented with a symbol that includes a curved line, indicating their temperature-dependent nature.

4. **Photoresistors**: Also known as light-dependent resistors (LDRs), these are depicted with a symbol that includes a light source, indicating their sensitivity to light.

C. Importance of Symbols in Circuit Diagrams

Using standardized symbols in circuit diagrams ensures clarity and consistency. Engineers can quickly identify components and their functions, facilitating effective communication and collaboration. This is particularly important in complex designs where multiple components interact.

III. Types of Resistors

A. Fixed Resistors

1. **Carbon Film Resistors**: Made from a carbon film deposited on a ceramic substrate, these resistors are cost-effective and widely used in general applications.

2. **Metal Film Resistors**: Known for their precision and stability, metal film resistors are often used in applications requiring high accuracy.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a core, these resistors can handle high power and are used in applications like power supplies.

B. Variable Resistors

1. **Potentiometers**: Commonly used for volume control in audio equipment, potentiometers allow users to adjust resistance manually.

2. **Rheostats**: Similar to potentiometers but typically used for higher power applications, rheostats can adjust current flow in circuits.

C. Specialty Resistors

1. **Thermistors**: These resistors change resistance with temperature, making them ideal for temperature sensing and compensation.

2. **Photoresistors**: Used in light-sensing applications, photoresistors change resistance based on light intensity.

3. **Surge Resistors**: Designed to handle high voltage spikes, surge resistors protect sensitive components in circuits.

IV. Key Parameters of Resistor Products

A. Resistance Value

1. **Ohm (Ω) Scale**: The resistance value is measured in ohms, with common values ranging from fractions of an ohm to millions of ohms (megaohms).

2. **Tolerance Levels**: Tolerance indicates how much the actual resistance can vary from the stated value, typically expressed as a percentage. Common tolerances include ±1%, ±5%, and ±10%.

B. Power Rating

1. **Definition and Importance**: The power rating indicates the maximum power a resistor can dissipate without overheating. Exceeding this rating can lead to failure.

2. **Common Power Ratings**: Resistors come in various power ratings, such as 1/8W, 1/4W, 1/2W, and higher, depending on the application.

C. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: This parameter indicates how much the resistance changes with temperature, typically expressed in parts per million per degree Celsius (ppm/°C).

2. **Impact on Performance**: A low temperature coefficient is desirable for precision applications, as it ensures stable performance across varying temperatures.

D. Voltage Rating

1. **Definition and Significance**: The voltage rating indicates the maximum voltage that can be applied across a resistor without risk of breakdown.

2. **Maximum Voltage Considerations**: Selecting a resistor with an appropriate voltage rating is crucial to prevent damage and ensure reliable operation.

E. Noise Characteristics

1. **Understanding Noise in Resistors**: Resistors can introduce noise into circuits, which can affect performance, especially in sensitive applications like audio and RF circuits.

2. **Importance in Sensitive Applications**: Low-noise resistors are essential in high-fidelity audio equipment and precision measurement devices.

V. Selecting the Right Resistor

A. Application Considerations

1. **Circuit Requirements**: Understanding the specific requirements of the circuit, including voltage, current, and power, is essential for selecting the right resistor.

2. **Environmental Factors**: Consideration of environmental conditions, such as temperature and humidity, can influence resistor performance.

B. Matching Resistor Types to Applications

1. **Audio Applications**: For audio circuits, low-noise and high-precision resistors are preferred to maintain sound quality.

2. **Power Electronics**: In power applications, wirewound resistors are often used due to their ability to handle high power levels.

3. **Signal Processing**: Metal film resistors are commonly used in signal processing applications for their stability and accuracy.

C. Common Mistakes in Resistor Selection

1. **Overlooking Power Ratings**: Failing to consider the power rating can lead to resistor failure and circuit malfunction.

2. **Ignoring Tolerance Levels**: Not accounting for tolerance can result in unexpected circuit behavior, especially in precision applications.

VI. Practical Applications of Resistors

A. Voltage Dividers

Resistors are commonly used in voltage divider circuits to produce a specific output voltage that is a fraction of the input voltage. This is useful in various applications, including sensor interfacing and signal conditioning.

B. Current Limiting

In LED circuits, resistors are used to limit the current flowing through the LED, preventing damage and ensuring proper operation.

C. Pull-up and Pull-down Resistors

These resistors are used in digital circuits to ensure that inputs to logic gates are at defined logic levels when not actively driven.

D. Signal Conditioning

Resistors play a crucial role in signal conditioning circuits, where they help filter and shape signals for further processing.

E. Feedback in Amplifiers

In amplifier circuits, resistors are used in feedback loops to control gain and stability, ensuring optimal performance.

VII. Conclusion

A. Recap of Resistor Importance

Resistors are indispensable components in electronic circuits, serving various functions that are critical to circuit performance and reliability.

B. Summary of Key Parameters

Understanding the key parameters of resistors, including resistance value, power rating, temperature coefficient, voltage rating, and noise characteristics, is essential for effective selection and application.

C. Final Thoughts on Resistor Selection and Usage

Selecting the right resistor involves careful consideration of application requirements and environmental factors. By understanding the various types of resistors and their parameters, engineers can make informed decisions that enhance circuit performance and reliability.

VIII. References

A. Suggested Reading

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Principles" by Albert Malvino and David Bates

B. Industry Standards and Guidelines

- IEC 60063: Preferred Numbers for Resistors

- ANSI/IEEE Std 141: IEEE Recommended Practice for Electric Power Distribution for Industrial Plants

C. Online Resources for Further Learning

- Electronics tutorials on websites like All About Circuits and Electronics-Tutorials.ws

- Online courses on platforms like Coursera and edX focusing on electronics and circuit design.

This comprehensive guide provides a thorough understanding of resistor circuit symbols and product series parameters, equipping readers with the knowledge needed to effectively select and utilize resistors in their electronic projects.

Popular Models of Resistor Wiring Diagrams

I. Introduction

A. Definition of Resistors

Resistors are fundamental electronic components that limit the flow of electric current in a circuit. They are used in various applications, from simple circuits to complex electronic devices. By providing resistance, they help control voltage and current levels, ensuring that components operate within their specified limits.

B. Importance of Resistor Wiring Diagrams

Resistor wiring diagrams are essential for understanding how to connect resistors in different configurations. These diagrams visually represent the arrangement of resistors and their connections, making it easier for engineers, technicians, and hobbyists to design and troubleshoot circuits. A clear wiring diagram can prevent errors and ensure that circuits function as intended.

C. Purpose of the Article

This article aims to explore popular models of resistor wiring diagrams, covering basic concepts, common configurations, advanced models, and practical considerations. By the end, readers will have a comprehensive understanding of resistor wiring and its applications.

II. Basic Concepts of Resistor Wiring

A. Understanding Resistance

1. Ohm's Law

Ohm's Law is a fundamental principle in electronics that relates voltage (V), current (I), and resistance (R). It states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points and inversely proportional to the resistance. The formula is expressed as:

\[ V = I \times R \]

This relationship is crucial for understanding how resistors function in a circuit.

2. Units of Measurement

Resistance is measured in ohms (Ω), named after the German physicist Georg Simon Ohm. Other units include milliohms (mΩ) and kilohms (kΩ), which are often used for very low or high resistance values, respectively.

B. Types of Resistors

1. Fixed Resistors

Fixed resistors have a constant resistance value and are the most common type used in circuits. They come in various forms, including carbon film, metal film, and wire-wound resistors.

2. Variable Resistors

Variable resistors, such as potentiometers and rheostats, allow users to adjust the resistance value. They are commonly used in applications like volume controls and light dimmers.

3. Specialty Resistors

Specialty resistors include thermistors, photoresistors, and varistors, which change resistance based on temperature, light, or voltage, respectively. These resistors are used in specific applications where variable resistance is required.

III. Common Resistor Wiring Configurations

A. Series Configuration

1. Definition and Characteristics

In a series configuration, resistors are connected end-to-end, and the same current flows through each resistor. The total resistance (R_total) is the sum of the individual resistances:

\[ R_{total} = R_1 + R_2 + R_3 + ... + R_n \]

2. Wiring Diagram Example

A simple series circuit with three resistors can be represented as follows:

```

+---[R1]---[R2]---[R3]---+

| |

+------------------------+

```

3. Applications and Use Cases

Series configurations are commonly used in applications where a specific voltage drop is required across each resistor, such as in LED circuits or voltage dividers.

B. Parallel Configuration

1. Definition and Characteristics

In a parallel configuration, resistors are connected across the same two points, providing multiple paths for current to flow. The total resistance (R_total) can be calculated using the formula:

\[ \frac{1}{R_{total}} = \frac{1}{R_1} + \frac{1}{R_2} + \frac{1}{R_3} + ... + \frac{1}{R_n} \]

2. Wiring Diagram Example

A simple parallel circuit with three resistors can be represented as follows:

```

+---[R1]---+

| |

+---[R2]---+

| |

+---[R3]---+

| |

+----------+

```

3. Applications and Use Cases

Parallel configurations are often used in applications where it is essential to maintain the same voltage across components, such as in power distribution systems and when connecting multiple devices to a single power source.

C. Series-Parallel Configuration

1. Definition and Characteristics

A series-parallel configuration combines both series and parallel connections. Some resistors are connected in series, while others are connected in parallel, allowing for more complex circuit designs.

2. Wiring Diagram Example

A series-parallel circuit can be represented as follows:

```

+---[R1]---+

| |

+---[R2]---+

| |

+---[R3]---+

| |

+---[R4]---+

| |

+----------+

```

3. Applications and Use Cases

Series-parallel configurations are used in more complex circuits, such as in audio systems where different speakers may be connected in various configurations to achieve desired sound quality.

IV. Advanced Resistor Wiring Models

A. Voltage Divider

1. Definition and Characteristics

A voltage divider is a simple circuit that produces a lower voltage from a higher voltage source. It consists of two resistors in series, and the output voltage (V_out) can be calculated using the formula:

\[ V_{out} = V_{in} \times \frac{R_2}{R_1 + R_2} \]

2. Wiring Diagram Example

A voltage divider can be represented as follows:

```

+---[R1]---+

| |

+---[R2]---+

| |

+----------+

```

3. Applications and Use Cases

Voltage dividers are commonly used in sensor applications, where a specific voltage level is required for processing signals.

B. Current Divider

1. Definition and Characteristics

A current divider is used to split the current among multiple parallel branches. The current through each branch can be calculated using the formula:

\[ I_n = I_{total} \times \frac{R_{total}}{R_n} \]

2. Wiring Diagram Example

A current divider can be represented as follows:

```

+---[R1]---+

| |

+---[R2]---+

| |

+---[R3]---+

| |

+----------+

```

3. Applications and Use Cases

Current dividers are often used in applications where it is necessary to measure or control current in different branches of a circuit.

C. Pull-Up and Pull-Down Resistors

1. Definition and Characteristics

Pull-up and pull-down resistors are used in digital circuits to ensure that inputs to logic gates are at a defined logic level. A pull-up resistor connects the input to a high voltage (Vcc), while a pull-down resistor connects it to ground (GND).

2. Wiring Diagram Example

A pull-up resistor can be represented as follows:

```

+---[R_pull-up]---+

| |

+---[Input]------+

| |

+-----------------+

```

3. Applications and Use Cases

Pull-up and pull-down resistors are commonly used in microcontroller circuits to prevent floating inputs and ensure reliable operation.

V. Practical Considerations in Resistor Wiring

A. Choosing the Right Resistor

1. Resistance Value

Selecting the appropriate resistance value is crucial for ensuring that the circuit operates correctly. The resistance value should be based on the desired current and voltage levels.

2. Power Rating

Resistors have a power rating that indicates the maximum power they can dissipate without overheating. It is essential to choose resistors with an adequate power rating to prevent damage.

B. Common Mistakes in Resistor Wiring

1. Incorrect Configuration

One of the most common mistakes is wiring resistors in the wrong configuration, leading to unexpected circuit behavior. It is essential to double-check wiring diagrams before finalizing connections.

2. Overheating Issues

Using resistors with insufficient power ratings can lead to overheating and failure. Always ensure that the selected resistor can handle the power it will dissipate.

C. Tools and Resources for Wiring Diagrams

1. Software and Online Tools

Various software and online tools are available for creating and simulating resistor wiring diagrams. Tools like LTspice, Fritzing, and Tinkercad can help visualize circuit designs.

2. Reference Materials

Books, articles, and online tutorials provide valuable information on resistor wiring and circuit design. Resources from reputable electronics websites and educational institutions can enhance understanding.

VI. Conclusion

A. Summary of Key Points

Resistor wiring diagrams are essential for understanding how to connect resistors in various configurations. This article covered basic concepts, common configurations, advanced models, and practical considerations for resistor wiring.

B. Importance of Understanding Resistor Wiring Diagrams

A solid understanding of resistor wiring diagrams is crucial for anyone working with electronics, from hobbyists to professional engineers. Proper wiring ensures that circuits function correctly and safely.

C. Encouragement for Further Learning and Experimentation

As technology continues to evolve, the importance of understanding resistor wiring will only grow. Readers are encouraged to explore further, experiment with different configurations, and deepen their knowledge of electronics.

VII. References

A. Books and Articles on Resistor Wiring

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronics for Dummies" by Cathleen Shamieh

B. Online Resources and Tutorials

- Electronics tutorials on websites like SparkFun and Adafruit

- YouTube channels dedicated to electronics education

C. Industry Standards and Guidelines

- IEEE standards for electronic components

- IPC standards for printed circuit board design

By understanding the popular models of resistor wiring diagrams, readers can enhance their skills in electronics and apply this knowledge to various projects and applications.

What are the Manufacturing Processes of the Latest Sensitive Resistors?

I. Introduction

Sensitive resistors are crucial components in modern electronics, playing a vital role in various applications ranging from temperature sensing to light detection. These resistors are designed to respond to changes in environmental conditions, making them essential in devices such as smartphones, medical equipment, and industrial sensors. As technology advances, the manufacturing processes for these sensitive resistors have evolved, incorporating new materials and techniques to enhance performance and reliability. This blog post will explore the types of sensitive resistors, the raw materials used in their production, key manufacturing processes, innovations, challenges, and future trends in the industry.

II. Types of Sensitive Resistors

Sensitive resistors come in various forms, each tailored for specific applications.

A. Overview of Different Types of Sensitive Resistors

1. **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations. They are widely used in temperature measurement and control systems.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these devices change resistance based on light intensity. They are commonly used in automatic lighting systems and cameras.

3. **Strain Gauges**: These resistors measure deformation or strain in materials. They are essential in structural health monitoring and load cells.

4. **Other Specialized Resistors**: This category includes piezoresistive sensors, gas sensors, and humidity sensors, each designed for specific environmental conditions.

B. Applications of Sensitive Resistors in Various Industries

Sensitive resistors find applications across multiple industries, including automotive, healthcare, consumer electronics, and aerospace. For instance, thermistors are used in automotive temperature sensors, while photoresistors are integral to smart lighting systems in homes and offices.

III. Raw Materials Used in Manufacturing

The performance of sensitive resistors largely depends on the materials used in their construction.

A. Conductive Materials

1. **Metal Oxides**: Commonly used in thermistors and gas sensors, metal oxides like tin oxide and zinc oxide exhibit significant changes in resistance with temperature and gas concentration.

2. **Carbon-Based Materials**: Carbon nanotubes and graphene are increasingly used due to their excellent electrical properties and sensitivity.

B. Insulating Materials

Insulating materials are crucial for preventing unwanted current flow and ensuring accurate measurements. Common insulators include ceramics and polymers.

C. Substrates and Packaging Materials

The choice of substrate affects the performance and durability of sensitive resistors. Common substrates include glass, silicon, and flexible polymers, while packaging materials must protect the resistors from environmental factors.

IV. Key Manufacturing Processes

The manufacturing of sensitive resistors involves several key processes, each critical to ensuring high performance and reliability.

A. Material Preparation

1. **Synthesis of Conductive Materials**: The first step involves synthesizing the conductive materials, which may include chemical vapor deposition for metal oxides or polymerization for carbon-based materials.

2. **Purification and Characterization**: After synthesis, materials undergo purification to remove impurities that could affect performance. Characterization techniques, such as X-ray diffraction and scanning electron microscopy, are used to analyze material properties.

B. Fabrication Techniques

1. **Screen Printing**: This technique is commonly used for thick-film resistors, where conductive paste is printed onto a substrate and then fired to create a resistive layer.

2. **Thin-Film Deposition**: Techniques like sputtering and chemical vapor deposition are used to create thin films of conductive materials, allowing for precise control over thickness and composition.

3. **Thick-Film Technology**: Similar to screen printing, thick-film technology involves applying a thicker layer of conductive material, suitable for applications requiring higher power handling.

4. **Laser Cutting and Etching**: These methods are employed to create precise patterns and shapes in the resistive materials, enhancing performance and functionality.

C. Assembly Processes

1. **Mounting on Substrates**: After fabrication, sensitive resistors are mounted onto substrates, which may involve adhesive bonding or soldering.

2. **Wire Bonding and Connections**: Electrical connections are made using wire bonding techniques, ensuring reliable communication with other electronic components.

D. Testing and Quality Control

1. **Electrical Testing**: Each resistor undergoes electrical testing to ensure it meets specified resistance values and performance criteria.

2. **Environmental Testing**: Resistors are subjected to various environmental conditions, such as temperature and humidity, to assess their reliability and durability.

3. **Reliability Assessments**: Long-term reliability tests are conducted to ensure that the resistors can withstand operational stresses over time.

V. Innovations in Manufacturing Techniques

The manufacturing landscape for sensitive resistors is continually evolving, driven by technological advancements.

A. Advances in Nanotechnology

Nanotechnology has enabled the development of resistors with enhanced sensitivity and faster response times. Nanoscale materials can provide greater surface area and improved electrical properties.

B. Use of 3D Printing in Resistor Manufacturing

3D printing technology allows for the rapid prototyping and production of complex resistor designs, reducing manufacturing time and costs while enabling customization.

C. Integration of Smart Materials

Smart materials that respond to environmental changes can be integrated into sensitive resistors, enhancing their functionality and application range.

D. Automation and Industry 4.0 in Production

The adoption of automation and Industry 4.0 principles in manufacturing processes has improved efficiency, reduced human error, and enabled real-time monitoring of production lines.

VI. Challenges in Manufacturing Sensitive Resistors

Despite advancements, several challenges persist in the manufacturing of sensitive resistors.

A. Material Limitations

The availability and cost of high-quality raw materials can limit production capabilities and affect performance.

B. Cost Considerations

Manufacturing sensitive resistors can be expensive, particularly when using advanced materials and technologies. Balancing performance with cost is a constant challenge.

C. Environmental Impact and Sustainability

The production processes for sensitive resistors can have environmental implications, necessitating the development of more sustainable practices and materials.

D. Meeting Industry Standards and Regulations

Manufacturers must adhere to strict industry standards and regulations, which can complicate the production process and increase costs.

VII. Future Trends in Sensitive Resistor Manufacturing

The future of sensitive resistor manufacturing is promising, with several trends emerging.

A. Emerging Materials and Technologies

Research into new materials, such as organic semiconductors and advanced composites, is expected to yield resistors with improved performance characteristics.

B. Potential Applications in IoT and Wearable Technology

As the Internet of Things (IoT) and wearable technology continue to grow, the demand for sensitive resistors that can operate in diverse environments will increase.

C. The Role of AI and Machine Learning in Manufacturing Processes

Artificial intelligence and machine learning are poised to revolutionize manufacturing processes, enabling predictive maintenance, quality control, and optimization of production lines.

VIII. Conclusion

In summary, sensitive resistors are integral to modern electronics, with diverse applications across various industries. The manufacturing processes for these components have evolved significantly, driven by advancements in materials and technology. While challenges remain, ongoing research and development promise to enhance the performance and sustainability of sensitive resistors. As we look to the future, the integration of emerging technologies and materials will undoubtedly shape the next generation of sensitive resistors, paving the way for innovative applications in an increasingly connected world.

IX. References

- Academic journals on materials science and electronics.

- Industry reports on sensor technology and manufacturing processes.

- Relevant books and articles on the advancements in resistor technology and applications.

This comprehensive overview of the manufacturing processes of sensitive resistors highlights their importance in modern electronics and the continuous innovations shaping their future.

What is the Market Prospect of High Voltage Resistors?

I. Introduction

High voltage resistors are essential components in electrical engineering, designed to withstand and operate under high voltage conditions. These resistors play a critical role in various applications, from power generation and distribution to consumer electronics. As the demand for reliable and efficient electrical systems continues to grow, the market for high voltage resistors is poised for significant expansion. This blog post explores the current market landscape, key drivers, challenges, applications, technological advancements, competitive dynamics, and future outlook for high voltage resistors.

II. Market Overview