NEW

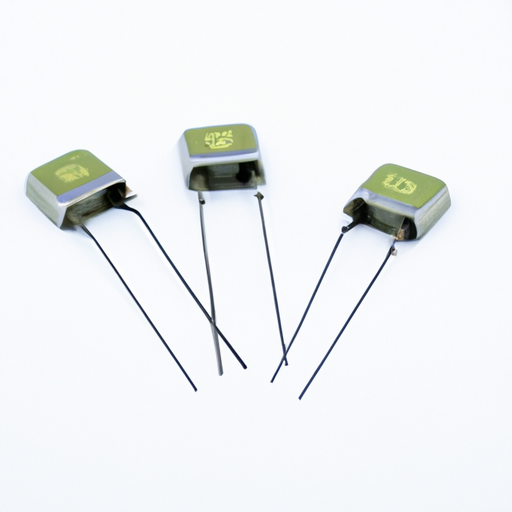

Application Development in FET and MOSFET Arrays: Insights and Success StoriesThe ECQ-P1H153GZ capacitor, while not directly related to FETs or MOSFET arrays, plays a role in the broader context of electronic circuit design where these components are utilized. Below, we explore the application development of FETs and MOSFET arrays, highlighting key technologies and notable success stories.

Key Technologies in FET and MOSFET Arrays1. High-Density Integration 2. Low On-Resistance (Rds(on)) 3. High-Speed Switching 4. Thermal Management 5. Integrated Drivers 6. Smart Power Management 1. Electric Vehicles (EVs) 2. Renewable Energy Systems 3. Consumer Electronics 4. Industrial Automation 5. Telecommunications Success Stories ConclusionThe development of FET and MOSFET arrays has had a profound impact across various industries, driving advancements in efficiency, performance, and compactness. As technology continues to evolve, we can anticipate further innovations that will expand the applications of these components, paving the way for new solutions in emerging fields such as electric mobility, renewable energy, and smart electronics. The integration of these technologies with components like the ECQ-P1H153GZ capacitor will continue to play a vital role in enhancing the performance and reliability of modern electronic systems.

Application Development in Single Zener Diodes for 2474-26L: Key Technologies and Success StoriesThe 2474-26L Zener diode is a notable component in the realm of electronic applications, particularly for voltage regulation and protection. Its unique characteristics make it suitable for a variety of uses across different industries. Below, we delve into the key technologies that leverage the capabilities of the 2474-26L and highlight some success stories that illustrate its impact.

Key Technologies1. Voltage Regulation2. Overvoltage Protection3. Signal Clipping4. Temperature Compensation5. Integration with Other Components1. Consumer Electronics2. Automotive Applications3. Telecommunications4. Industrial Automation5. Medical Devices Success Stories ConclusionThe 2474-26L Zener diode exemplifies the critical role of Zener diodes in modern electronic applications. Its capabilities in voltage regulation, overvoltage protection, and signal clipping make it an invaluable component across various sectors, including consumer electronics, automotive, telecommunications, industrial automation, and medical devices. As technology continues to advance, the significance of Zener diodes like the 2474-26L in ensuring the reliability and performance of electronic systems will only grow, paving the way for innovative applications and enhanced device functionality.

Overview of CFR-25JB-52-100R Diode ArraysThe CFR-25JB-52-100R is a specific type of diode array that exemplifies the core functional technology and applications of diode arrays in modern electronics. Below is a detailed overview of its core functionalities and potential application development cases.

Core Functional Technology of Diode Arrays1. Integrated Design: The CFR-25JB-52-100R integrates multiple diodes into a single package, which minimizes the footprint on printed circuit boards (PCBs) and simplifies the overall design process. This integration is particularly beneficial in compact electronic devices. 2. Versatile Functionality Diode arrays like the CFR-25JB-52-100R can perform various essential functions:3. Diverse Diode Types The array may include different diode types, such as:4. Thermal Management: The design of the CFR-25JB-52-100R incorporates features for effective heat dissipation, which is critical in high-power applications to maintain reliability and performance.

5. Reduced Component Count: By integrating multiple diodes into one package, the CFR-25JB-52-100R reduces the number of discrete components required, leading to lower assembly costs and improved reliability.

Application Development Cases1. Power Supply Circuits: The CFR-25JB-52-100R is ideal for use in power supply circuits, where it can efficiently rectify AC to DC. Its ability to handle high current loads makes it suitable for power adapters, converters, and battery chargers.

2. Signal Protection: In sensitive electronic systems, the diode array can protect against voltage spikes and transients. It is particularly useful in ESD protection circuits, safeguarding integrated circuits (ICs) and other components from damage.

3. LED Driver Circuits: The CFR-25JB-52-100R can be employed in LED driver applications to manage current flow, ensuring consistent brightness across multiple LEDs. This is crucial for applications in automotive lighting, displays, and architectural lighting.

4. Switching Regulators: In switching power supplies, the diode array can be utilized for synchronous rectification, enhancing efficiency by minimizing power losses during the switching process. This is particularly important in high-efficiency power management systems.

5. RF Applications: The CFR-25JB-52-100R can be used in RF applications for signal mixing and detection. It plays a role in demodulating signals and is often found in RF front-end modules, contributing to improved communication performance.

6. Automotive Electronics: In the automotive sector, diode arrays are used for battery management systems, lighting control, and protection circuits against voltage spikes from inductive loads, ensuring the reliability of electronic systems in vehicles.

7. Consumer Electronics: The CFR-25JB-52-100R is applicable in various consumer electronics, including audio equipment and power management systems, where signal integrity and protection are paramount.

ConclusionThe CFR-25JB-52-100R diode array exemplifies the critical role of diode arrays in modern electronic design. By providing a compact, efficient, and reliable solution for a wide range of applications, it enhances performance and simplifies design processes across various sectors, including power management, signal processing, and protection circuits. For further insights and specific case studies, exploring technical journals, manufacturer white papers, and industry publications focused on semiconductor technology will provide valuable information.

Application Development in RF FETs and MOSFETs for CFR-25JB-52-100K: Key Technologies and Success StoriesThe integration of RF FETs (Field Effect Transistors) and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) into RF applications, particularly in conjunction with components like the CFR-25JB-52-100K resistor, showcases the evolution of technology in high-frequency and power applications. While the CFR-25JB-52-100K is a resistor, its role in RF circuits is significant, especially when paired with active components like RF FETs and MOSFETs. Below, we explore key technologies and notable success stories in this domain.

Key Technologies1. High-Frequency Performance2. Power Amplification3. Integration with Passive Components4. Thermal Management5. Digital Control and Modulation6. GaN and SiC Technologies1. Telecommunications2. Satellite Communications3. Consumer Electronics4. Automotive Applications5. Medical Devices Success Stories ConclusionThe application development of RF FETs and MOSFETs, particularly in conjunction with components like the CFR-25JB-52-100K resistor, has led to significant advancements across various industries. By focusing on high-frequency performance, power amplification, and effective integration with passive components, these technologies have enabled the creation of efficient, reliable, and high-performance RF systems. As technology continues to advance, we can anticipate further innovations and success stories in the realm of RF applications, driving progress in telecommunications, consumer electronics, automotive systems, and medical devices.

CFR-50JB-52-100K RF Diodes: Core Functional Technology and Application Development CasesThe CFR-50JB-52-100K RF diode is a specialized semiconductor device designed for high-frequency applications within the radio frequency (RF) spectrum. RF diodes, including the CFR-50JB-52-100K, are essential components in various RF circuits, performing critical functions such as rectification, mixing, and signal modulation. Below, we delve into the core functional technologies of RF diodes and explore several application development cases that highlight their effectiveness.

Core Functional Technology of RF Diodes1. Rectification2. Mixing3. Clipping and Clamping4. Tuning and Filtering5. Switching1. RF Power Measurement2. Mixers in Communication Systems3. Signal Demodulation4. Protection Circuits5. RF Switching Applications Application Development Cases ConclusionThe CFR-50JB-52-100K RF diode exemplifies the critical role that RF diodes play in modern electronic systems. Their ability to rectify, mix, and switch signals makes them indispensable in a wide range of applications, from telecommunications to broadcasting and beyond. Understanding the core technologies and application cases of RF diodes can help engineers and developers design more effective and reliable RF systems, ultimately enhancing performance and user experience in various electronic applications.

Overview of Single Diodes: Core Functional Technology and ApplicationsThe CFR-25JB-52-1R8 is a specific type of single diode, and while I cannot access proprietary articles or specific case studies, I can provide a comprehensive overview of the core functional technology of single diodes and their applications, which are relevant to components like the CFR-25JB-52-1R8.

Core Functional Technology of Single Diodes1. Basic Functionality2. Types of Diodes3. Key Parameters1. Rectification2. Voltage Regulation3. Signal Demodulation4. Clamping and Clipping Circuits5. LED Applications1. Power Supply Design2. LED Lighting Solutions3. Automotive Applications4. Telecommunications Applications of Single Diodes Development Cases ConclusionSingle diodes, including the CFR-25JB-52-1R8, are integral components in various electronic applications. Their ability to control current flow, regulate voltage, and facilitate signal processing makes them indispensable in modern electronics. Understanding their core technology and applications can lead to innovative designs and improved performance in electronic systems. For specific articles and case studies, consulting technical journals, manufacturer datasheets, and industry publications would provide more detailed insights into the practical applications and advancements in diode technology.

Application Development in Single IGBTs for CFR-25JB-52-1M8: Key Technologies and Success StoriesThe development of applications utilizing single Insulated Gate Bipolar Transistors (IGBTs), such as the CFR-25JB-52-1M8, involves a combination of advanced technologies and innovative strategies. Below is a detailed overview of the key technologies involved and notable success stories that illustrate the practical applications of these components.

Key Technologies1. IGBT Technology2. Thermal Management3. Gate Drive Circuits4. Modulation Techniques5. Integration with Digital Control6. Simulation and Modeling7. Packaging and Reliability1. Renewable Energy Inverters2. Electric Vehicle (EV) Drives3. Industrial Motor Drives4. HVDC Transmission5. Consumer Electronics Success Stories ConclusionThe application development of single IGBTs, such as the CFR-25JB-52-1M8, is driven by advancements in technology, including improved thermal management, sophisticated control strategies, and integration with digital systems. The success stories across various industries highlight the versatility and effectiveness of IGBT technology in enhancing performance, efficiency, and reliability in power electronic applications. As technology continues to evolve, further innovations and applications of IGBTs are expected, particularly in emerging fields such as electric mobility and renewable energy systems. The ongoing research and development in this area promise to unlock new possibilities and drive the next generation of power electronics.

Application Development in DIACs, SIDACs for MM74HC259N: Key Technologies and Success StoriesThe MM74HC259N is a high-speed CMOS 8-bit addressable latch that plays a crucial role in digital applications, particularly in data storage, control systems, and interfacing with microcontrollers. While DIACs (Diode for Alternating Current) and SIDACs (Silicon Diode for Alternating Current) serve different functions, they can be effectively integrated into systems that utilize the MM74HC259N for enhanced control and switching capabilities.

Key Technologies1. Digital Logic Design2. Microcontroller Integration3. Power Electronics4. Signal Conditioning5. PCB Design6. Simulation Tools1. Home Automation Systems2. Motor Control Applications3. Lighting Control4. Industrial Automation5. Consumer Electronics Success Stories ConclusionThe integration of the MM74HC259N with DIACs and SIDACs can lead to innovative solutions across various fields, including home automation, industrial control, and consumer electronics. By understanding the key technologies and successful applications, developers can create efficient and effective systems that leverage the strengths of each component, ultimately enhancing functionality and performance in their designs.

Application Development in Crystal Oscillators and Resonators: CFR-25JB-52-1R6The development of applications in the field of crystal oscillators and resonators, particularly for components like the CFR-25JB-52-1R6, is a dynamic area that leverages various advanced technologies. Below is a detailed overview of the key technologies, application areas, and notable success stories that illustrate the advancements and impact of these components.

Key Technologies1. Quartz Crystal Technology2. Microelectromechanical Systems (MEMS)3. Surface Acoustic Wave (SAW) Devices4. Integrated Circuit (IC) Technology5. Simulation and Modeling Tools6. Automated Testing and Quality Control1. Telecommunications2. Consumer Electronics3. Automotive4. Industrial Automation5. Medical Devices1. Telecom Industry2. Consumer Electronics3. Automotive Sector4. Medical Devices Application Areas Success Stories ConclusionThe development of applications for crystal oscillators and resonators like the CFR-25JB-52-1R6 is propelled by advancements in technology, integration capabilities, and the increasing demand for high-performance, reliable components across various industries. Success stories from telecommunications, consumer electronics, automotive, and medical sectors highlight the transformative impact of these technologies on product innovation and market success. As the need for precision timing and frequency control continues to rise, ongoing research and development in this field will likely yield even more innovative solutions, further enhancing the capabilities of crystal oscillators and resonators.

Application Development in VCOs (Voltage Controlled Oscillators) for CFR-50JB-52-1M6: Key Technologies and Success StoriesVoltage Controlled Oscillators (VCOs) are essential components in a wide range of applications, particularly in communication systems, signal processing, and frequency synthesis. The CFR-50JB-52-1M6 is a specific model of VCO known for its performance characteristics and frequency range. Below, we explore key technologies that drive VCO development and highlight notable success stories that illustrate their application.

Key Technologies in VCO Development1. Phase-Locked Loop (PLL) Technology2. Low Phase Noise Design3. Temperature Compensation4. Integration with RF Front-End5. Digital Control Interfaces6. Advanced Fabrication Techniques1. Telecommunications2. Satellite Communication3. Consumer Electronics4. Automotive Applications5. Test and Measurement Equipment Success Stories ConclusionThe development of VCOs, particularly models like the CFR-50JB-52-1M6, has been propelled by advancements in technology and the increasing demand for high-performance communication systems. By leveraging key technologies such as PLLs, low phase noise design, and digital control interfaces, VCOs have achieved success across various industries, from telecommunications to automotive applications. As technology continues to evolve, the role of VCOs in enabling innovative solutions is expected to expand, paving the way for new applications and improved performance in existing systems.

CFR-25JB-52-1K6 Programmable Oscillators: Core Functional Technology and Application Development Overview of Programmable OscillatorsProgrammable oscillators are essential components in modern electronics, providing precise frequency signals that can be tailored to specific application needs. The CFR-25JB-52-1K6 model exemplifies the capabilities of programmable oscillators, offering features such as frequency programmability, low power consumption, and high stability, making it suitable for a wide range of applications. Core Functional Technology1. Frequency Programmability2. Low Phase Noise3. Temperature Stability4. Low Power Consumption5. Digital Control Interface6. Compact Form Factor1. Telecommunications2. Consumer Electronics3. Industrial Automation4. Medical Devices5. Automotive Applications6. IoT Devices Application Development Cases ConclusionThe CFR-25JB-52-1K6 programmable oscillator represents a significant advancement in frequency generation technology, offering flexibility, stability, and efficiency. Its applications span various industries, from telecommunications to medical devices, showcasing its versatility and effectiveness in addressing modern electronic design challenges. As technology continues to evolve, programmable oscillators like the CFR-25JB-52-1K6 will play an increasingly critical role in the development of innovative solutions across multiple sectors, driving advancements in performance and functionality.

Application Development in Switching Converters and SMPS Transformers: CFR-50JB-52-1K6The development of applications in switching converters and SMPS (Switched-Mode Power Supply) transformers, such as the CFR-50JB-52-1K6, is a dynamic field that integrates various technologies and methodologies to enhance performance, efficiency, and reliability. Below is a detailed overview of key technologies and notable success stories in this domain.

Key Technologies1. High-Frequency Operation2. Magnetic Materials3. Control Techniques4. Topology Innovations5. Thermal Management6. EMI/EMC Compliance7. Simulation and Modeling8. Integration of Power Electronics1. Consumer Electronics2. Renewable Energy Systems3. Telecommunications4. Electric Vehicles (EVs)5. Industrial Automation Success Stories ConclusionThe application development in switching converters and SMPS transformers, exemplified by the CFR-50JB-52-1K6, is characterized by continuous advancements in technology, materials, and design methodologies. The success stories across various industries underscore the critical role these technologies play in achieving energy efficiency, compactness, and reliability in power supply solutions. As the demand for innovative and efficient power solutions continues to rise, the importance of switching converters and SMPS transformers will only grow, shaping the future landscape of power electronics.

Overview of CFR-50JB-52-1R6 Isolation Transformers and AutotransformersThe CFR-50JB-52-1R6 model represents a significant advancement in transformer technology, particularly in the realms of isolation and autotransformation. These transformers are essential in various applications, providing solutions for power distribution, voltage regulation, and safety across multiple industries.

Core Functional Technologies Isolation Transformers

1. **Electromagnetic Induction**: The primary and secondary windings are magnetically coupled, allowing for voltage transformation while maintaining electrical isolation. This is crucial for protecting sensitive equipment from power surges and electrical noise.2. Voltage Transformation: Isolation transformers can step up or step down voltage levels, making them versatile for different applications. They ensure that the output voltage remains stable, which is vital for sensitive electronic devices. 3. Safety Features: By isolating the load from the power source, isolation transformers significantly reduce the risk of electrical shocks and ground loops, enhancing overall safety in electrical systems.

4. Noise Filtering: These transformers are effective in filtering out electrical noise, which is particularly beneficial in environments with sensitive electronic equipment, such as laboratories and data centers.

Autotransformers

1. **Single Winding Design**: Autotransformers utilize a single winding that serves as both the primary and secondary winding. This design allows for a more compact and lightweight transformer compared to traditional isolation transformers.2. Higher Efficiency: Due to the shared winding, autotransformers exhibit lower copper losses, making them more efficient for voltage transformation.

3. Versatile Voltage Adjustment: Autotransformers can easily step up or step down voltage levels, making them suitable for a wide range of applications, from industrial machinery to consumer electronics.

4. Space-Saving Design: Their compact design is advantageous in applications where space is limited, such as in residential or commercial electrical systems.

Application Development Cases 1. Industrial Machinery

- **Example**: CNC machines and robotic arms often require stable voltage supplies to operate effectively. Isolation transformers are used to ensure that these machines receive a consistent voltage, minimizing the risk of operational disruptions.

- **Benefits**: Enhanced safety, reduced electrical noise, and improved equipment longevity. 2. Medical Equipment

- **Example**: Isolation transformers are critical in powering sensitive medical devices like MRI machines and patient monitoring systems. They ensure that patients are protected from electrical faults while maintaining device reliability.

- **Benefits**: Electrical isolation enhances patient safety, while noise reduction improves the accuracy of diagnostic equipment. 3. Audio and Video Equipment

- **Example**: In professional audio systems, isolation transformers are employed to eliminate ground loops that can cause hum and noise in sound systems.

- **Benefits**: Improved sound quality and clearer video signals, leading to a better overall user experience. 4. Renewable Energy Systems

- **Example**: In solar power installations, autotransformers are used to step up the voltage from solar panels to match grid requirements, facilitating efficient energy transfer.

- **Benefits**: Increased efficiency and reduced costs compared to traditional transformers, making renewable energy systems more viable. 5. Electric Vehicles (EVs)

- **Example**: Autotransformers are utilized in EV charging stations to adjust voltage levels for different types of electric vehicles, ensuring compatibility and efficiency.

- **Benefits**: Flexibility in charging options and improved energy efficiency, supporting the growing EV market. ConclusionThe CFR-50JB-52-1R6 model exemplifies the advancements in transformer technology, offering effective solutions that enhance safety, efficiency, and performance across various applications. As industries continue to evolve, the demand for reliable and effective transformer solutions will only grow, driving further innovation in this field. The integration of isolation transformers and autotransformers into modern electrical systems is crucial for meeting the challenges of today's technological landscape, ensuring that power distribution is safe, efficient, and adaptable to future needs.

CFR-25JB-52-1M5 Specialty Transformer: Core Functional Technologies and Application Development CasesThe CFR-25JB-52-1M5 Specialty Transformer, while not widely recognized in general literature, exemplifies the advancements and specific functionalities found in specialty transformers. These transformers are engineered for unique applications that necessitate particular electrical characteristics. Below, we delve into the core functional technologies and application development cases relevant to specialty transformers, including the CFR-25JB-52-1M5.

Core Functional Technologies of Specialty Transformers1. Custom Winding Configurations2. High Efficiency and Low Losses3. Thermal Management4. Isolation and Safety Features5. Compact Design6. Smart Technology Integration1. Renewable Energy Systems2. Electric Vehicles (EVs)3. Industrial Automation4. Telecommunications5. Medical Equipment6. Data Centers Application Development Cases ConclusionSpecialty transformers, including models like the CFR-25JB-52-1M5, are vital components in various advanced applications across multiple industries. Their unique designs and technologies enable them to meet specific requirements, ensuring efficiency, safety, and reliability. As technology continues to evolve, the demand for specialized solutions in power management will likely increase, driving further innovation in transformer design and application. The ongoing development of specialty transformers will play a crucial role in supporting the growth of renewable energy, electric vehicles, and other cutting-edge technologies.

Application Development in Power Transformers for CFR-50JB-52-1M5: Key Technologies and Success StoriesDeveloping applications for power transformers, such as the CFR-50JB-52-1M5, involves leveraging various key technologies and methodologies to enhance performance, reliability, and efficiency. Below are some key technologies and success stories related to application development in power transformers.

Key Technologies1. Smart Grid Integration2. Advanced Materials3. Digital Twin Technology4. Condition Monitoring Systems5. Energy Efficiency Improvements6. Renewable Energy Integration1. Predictive Maintenance Implementation2. Smart Transformer Deployment3. Renewable Integration Project4. Energy Efficiency Upgrade5. Digital Twin for Design Optimization Success Stories ConclusionThe application development for power transformers like the CFR-50JB-52-1M5 is rapidly evolving, driven by advancements in technology and the increasing demand for efficient and reliable energy solutions. By leveraging smart technologies, advanced materials, and innovative design practices, companies can enhance the performance and reliability of transformers, leading to significant operational benefits and success stories in the field. The ongoing integration of these technologies will continue to shape the future of power transformers, making them more efficient, resilient, and capable of meeting the challenges of modern energy demands.

Application Development in Audio Transformers for CFR-50JB-52-1K5: Key Technologies and Success StoriesDeveloping audio transformers, such as the CFR-50JB-52-1K5, involves a combination of key technologies and methodologies that enhance performance, reliability, and application versatility. Below are the key technologies and notable success stories related to audio transformer development.

Key Technologies1. Magnetic Core Materials2. Winding Techniques3. Shielding and Grounding4. Simulation and Modeling5. Quality Control and Testing1. High-End Audio Equipment2. Professional Audio Applications3. Consumer Electronics4. Musical Instrument Amplifiers5. Research and Development Success Stories ConclusionThe development of audio transformers like the CFR-50JB-52-1K5 is a complex interplay of materials science, engineering, and audio technology. By leveraging advanced materials, innovative design techniques, and rigorous testing, manufacturers can create transformers that meet the demanding requirements of modern audio applications. Success stories from various sectors highlight the importance of these components in achieving high-quality sound reproduction and the ongoing evolution of audio technology. As the industry continues to innovate, the role of audio transformers will remain critical in delivering exceptional audio experiences.

Overview of CFR-50JB-52-1R5 Resistor and Its AccessoriesThe CFR-50JB-52-1R5 is a specific model of a resistor that exemplifies the core functionalities and applications of resistors in electronic circuits. Understanding its technology and the accessories that enhance its performance is crucial for effective application development.

Core Functional Technology of Resistors1. Basic Functionality: Resistors are fundamental components in electronic circuits, primarily used to control current flow. They convert electrical energy into heat, thereby limiting the amount of current that can pass through a circuit. 2. Types of Resistors3. Power Rating: The CFR-50JB-52-1R5 is rated for a specific power handling capacity, which is crucial for ensuring that it can operate without overheating in high-power applications.

4. Tolerance: This specification indicates the permissible variation in resistance, which is vital for precision applications where exact resistance values are necessary.

5. Temperature Coefficient: This parameter describes how the resistance value changes with temperature, impacting the resistor's performance in varying environmental conditions.

Accessories for Resistors1. Heat Sinks: Essential for high-power resistors, heat sinks dissipate heat to prevent thermal damage, ensuring reliability and longevity in applications.

2. Mounting Hardware: Proper mounting solutions, such as brackets and clips, are necessary for secure installation, which can affect the performance and reliability of the resistor in a circuit.

3. Circuit Protection Devices: Accessories like fuses and circuit breakers protect resistors from overcurrent situations, enhancing the safety and durability of electronic systems.

4. Testing Equipment: Tools such as multimeters and oscilloscopes are critical for measuring resistance, voltage, and current, ensuring that resistors function correctly within their intended applications.

5. PCB Design Tools: Software that aids in designing printed circuit boards (PCBs) can optimize the layout and integration of resistors and their accessories, improving overall circuit performance.

Application Development Cases1. Power Supply Circuits: Resistors are integral in voltage divider circuits, which create reference voltages for various components, ensuring stable operation in power supply designs.

2. Signal Conditioning: In sensor applications, resistors filter signals, allowing only desired frequencies to pass, which is crucial for accurate data acquisition.

3. LED Drivers: Resistors limit current to LEDs, preventing damage and ensuring consistent brightness, which is essential in lighting applications.

4. Audio Equipment: In audio circuits, resistors control gain and shape frequency response, significantly impacting sound quality and performance.

5. Temperature Sensors: Thermistors, a type of resistor, are widely used in temperature sensing applications, providing critical data for systems like HVAC and industrial processes.

ConclusionThe CFR-50JB-52-1R5 resistor is a vital component in various electronic applications, demonstrating the importance of understanding its core functionalities and the role of accessories. By leveraging appropriate accessories and comprehending the underlying technology, engineers can develop effective applications across multiple industries. Whether in power management, signal processing, or sensor integration, the combination of resistors and their accessories is essential for creating reliable and efficient electronic systems.

基本

文件

流程

错误

SQL

调试

- 请求信息 : 2025-06-15 10:43:31 HTTP/2.0 GET : https://ruilongic.cn/en/news.html

- 运行时间 : 0.214950s [ 吞吐率:4.65req/s ] 内存消耗:4,583.70kb 文件加载:201

- 查询信息 : 0 queries

- 缓存信息 : 2 reads,0 writes

- 会话信息 : SESSION_ID=68c7ad2ae1aac4df8fbd55e6635550a8

- CONNECT:[ UseTime:0.000975s ] mysql:host=127.0.0.1;port=3306;dbname=ruilongic_cn;charset=utf8mb4

- SHOW FULL COLUMNS FROM `moban_site` [ RunTime:0.003865s ]

- SELECT * FROM `moban_site` WHERE `lang` = 'en' LIMIT 1 [ RunTime:0.001577s ]

- SHOW FULL COLUMNS FROM `moban_columns` [ RunTime:0.003686s ]

- SELECT * FROM `moban_columns` WHERE `state` = 1 AND `lang` = 'en' ORDER BY `sort` ASC [ RunTime:0.001869s ]

- SHOW FULL COLUMNS FROM `moban_news` [ RunTime:0.003816s ]

- SELECT * FROM `moban_news` WHERE `lang` = 'en' AND `state` = 1 LIMIT 1 [ RunTime:0.001625s ]

- SHOW FULL COLUMNS FROM `moban_news_category` [ RunTime:0.002566s ]

- SELECT * FROM `moban_news_category` WHERE `lang` = 'en' ORDER BY `id` ASC [ RunTime:0.001158s ]

- SHOW FULL COLUMNS FROM `moban_single_page` [ RunTime:0.003394s ]

- SELECT * FROM `moban_single_page` WHERE `id` IN (0,28,34,73,78,80,82) AND `state` = 1 AND `lang` = 'en' [ RunTime:0.001727s ]

- SELECT * FROM `moban_single_page` WHERE `id` IN (0,2,68) AND `state` = 1 AND `lang` = 'en' [ RunTime:0.001094s ]

- SHOW FULL COLUMNS FROM `moban_link` [ RunTime:0.002215s ]

- SELECT * FROM `moban_link` WHERE `state` = 1 ORDER BY `sort` ASC [ RunTime:0.002946s ]

- SELECT COUNT(*) AS think_count FROM `moban_news` WHERE `state` = 1 AND `lang` = 'en' AND `is_draft` = 0 LIMIT 1 [ RunTime:0.008092s ]

- SELECT * FROM `moban_news` WHERE `state` = 1 AND `lang` = 'en' AND `is_draft` = 0 ORDER BY `sort` DESC,`id` DESC LIMIT 0,25 [ RunTime:0.029720s ]

- SELECT * FROM `moban_columns` WHERE `lang` = 'en' AND `link` = '/news' LIMIT 1 [ RunTime:0.003504s ]

0.236992s