Quantity

Price

Total price

3000

$0.3360

$1,008.0000

| TYPE | DESCRIPTION |

| Mfr | STMicroelectronics |

| Series | - |

| Package | Bulk |

| Product Status | ACTIVE |

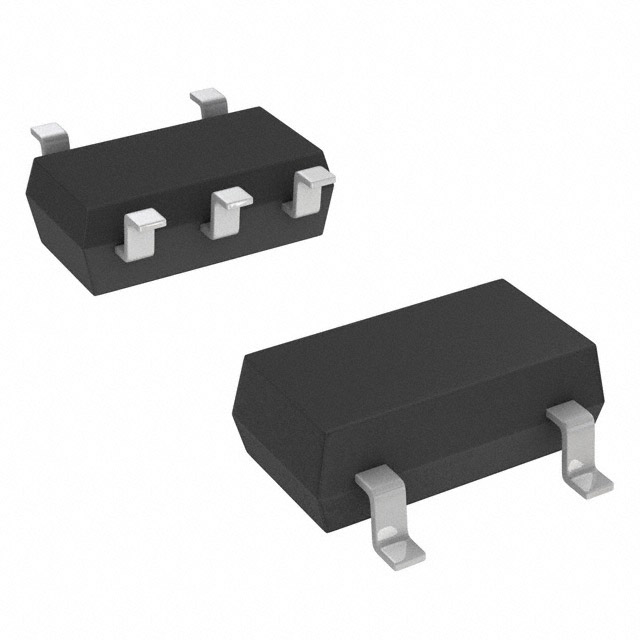

| Package / Case | 5-TSSOP, SC-70-5, SOT-353 |

| Output Type | Single Ended, Rail-to-Rail |

| Mounting Type | Surface Mount |

| Amplifier Type | Standard |

| Operating Temperature | -40°C ~ 125°C |

| Current - Supply | 75µA |

| Slew Rate | 0.4V/µs |

| Gain Bandwidth Product | 1 MHz |

| Current - Input Bias | 1 pA |

| Voltage - Input Offset | 750 µV |

| Supplier Device Package | SC-70-5 |

| Number of Circuits | 1 |

| Current - Output / Channel | 30 mA |

| Voltage - Supply Span (Min) | 1.8 V |

| Voltage - Supply Span (Max) | 5.5 V |